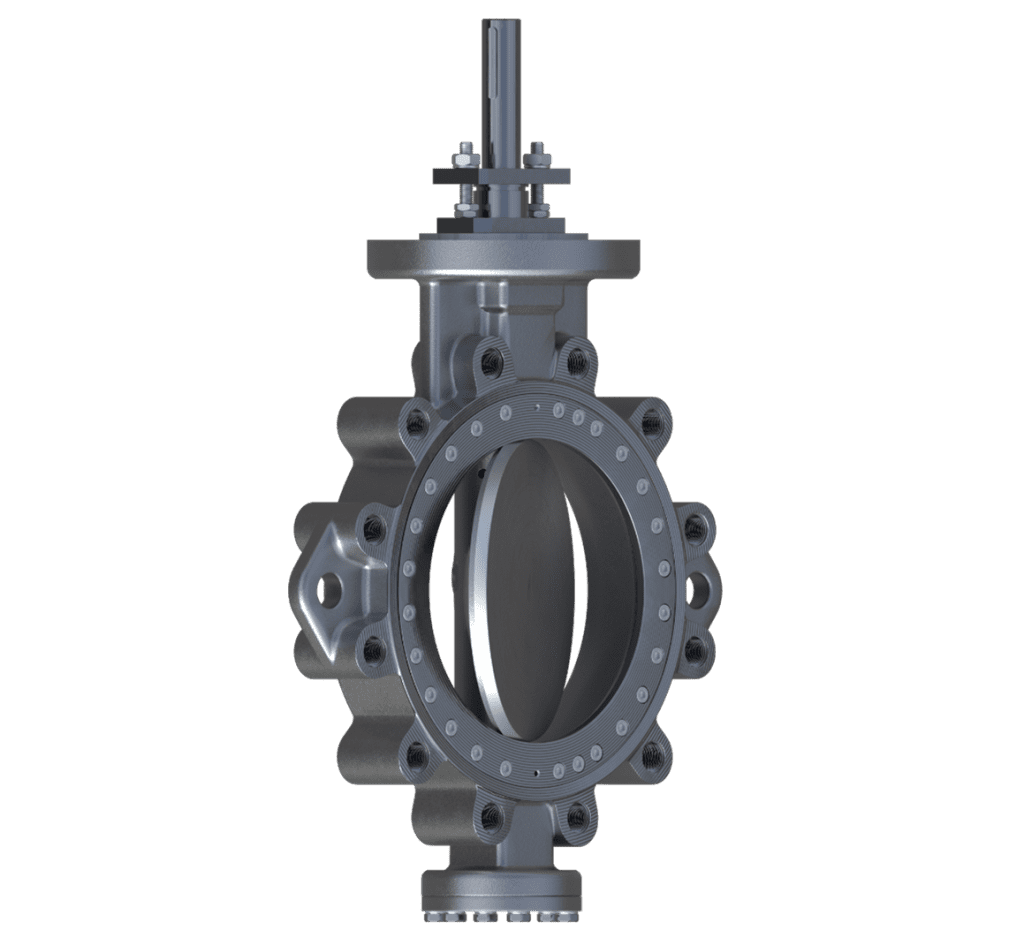

Severn are breaking tradition with the innovative OCT Butterfly Valve and lifecycle enhancement service.

In the fast-paced industrial landscape, the emphasis on sustainability and cost-effectiveness has never been greater. Severn’s Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve is at the forefront of a new era in valve technology, where the focus shifts from immediate replacements to intelligent lifecycle enhancement and repair strategies. This paradigm shift not only promotes sustainable valve maintenance but also ensures safe operations, reduced downtime, helping you achieve your core remits.

Lifecycle Enhancement: Prolonging Valve Longevity

The traditional approach to valve maintenance often involves a “replace-first” mentality. However, Severn’s OCT TOV Butterfly Valve challenges this norm by offering a comprehensive lifecycle enhancement program. Through cutting-edge innovative engineering and materials, the OCT TOV Butterfly Valve is designed to withstand harsh operating conditions, ensuring a longer lifespan with its patented Oblique Cone Technology Triple Offset capabilities for both isolation and control applications.

By prioritizing lifecycle enhancement, industries can optimise their assets, reduce overall operational costs, and minimise the environmental footprint associated with the manufacturing and disposal of new valves.

Repair Intelligence: Smart Solutions for Complex Issues

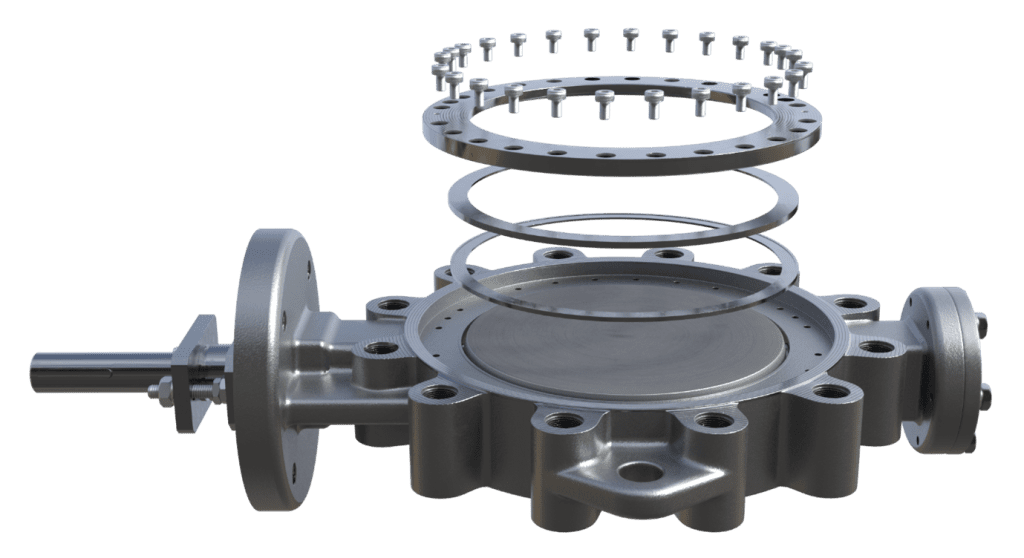

The OCT TOV Butterfly Valve affirms the concept of Severn’s repair intelligence as the valves are designed with modular components, facilitating easy disassembly and reassembly during repairs. This not only reduces maintenance costs but also minimises the need for complete valve replacements, contributing to a more sustainable and cost-effective approach to industrial operations.

Sustainable Valve Maintenance: A Green Approach

Severn’s commitment to sustainability goes beyond the valve’s design. The OCT TOV Butterfly Valve promotes a circular economy by encouraging refurbishment and reconditioning of components. With our expert team of service engineers based globally, we can retrofit, service and repair any of our Butterfly valves on site if performance has dropped or specification or operating conditions have changed, this ensures production downtime is kept to a minimum.

Furthermore, sustainable valve maintenance aligns with global initiatives to reduce carbon emissions. By extending the life of industrial equipment, companies can decrease their carbon footprint associated with manufacturing and disposal, contributing to a greener and more environmentally responsible future.

Safe Operations and Reduced Downtime: The Ultimate Value Proposition

The OCT TOV Butterfly Valve prioritise safety through rigorous testing and compliance with industry standards such as API 598. By implementing repair intelligence and lifecycle enhancement strategies, Severn can ensure the continued reliability and safety of their valves and valve systems.

Moreover, the ability to address issues proactively minimise unexpected costly downtime. This not only enhances operational efficiency but also safeguards against potential safety hazards, ensuring a secure working environment for personnel.

Environmental Impact: A Positive Footprint for Future Generations

By choosing repair over replacement and embracing Severn’s lifecycle enhancement, industries using Severn’s OCT TOV Butterfly Valve actively contribute to reducing the environmental impact of their operations. Through sustainable valve maintenance practices, companies can align with global environmental goals, demonstrating corporate responsibility and leadership in their respective sectors.

Severn’s OCT TOV Butterfly Valve signifies a paradigm shift in the industrial valve landscape. By championing lifecycle enhancement, repair intelligence, and sustainable valve maintenance, this product offers not just cutting-edge technology but a comprehensive solution for industries seeking a balance between operational efficiency, environmental responsibility, and cost-effectiveness. In a world where every decision impacts the planet, choosing to repair, not replace, is a step towards a more sustainable and resilient future.

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 25 November 2024 Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions