Operators are under increasing focus on reducing fugitive emissions for both onshore and offshore assets, to reduce harmful emission to achieve their core imperatives of safe operations and minimum downtime.

Fugitive emissions is a hot topic that will only become more critical in the environmentally conscious world we now live in. Fugitive emissions are a leak of gas or vapour, normally due to poor maintenance or packing sets being utilised without a true understanding of the application, leading to potential product performance issues and a variety of costly, detrimental failures.

How are Severn meeting the challenges of emission control?

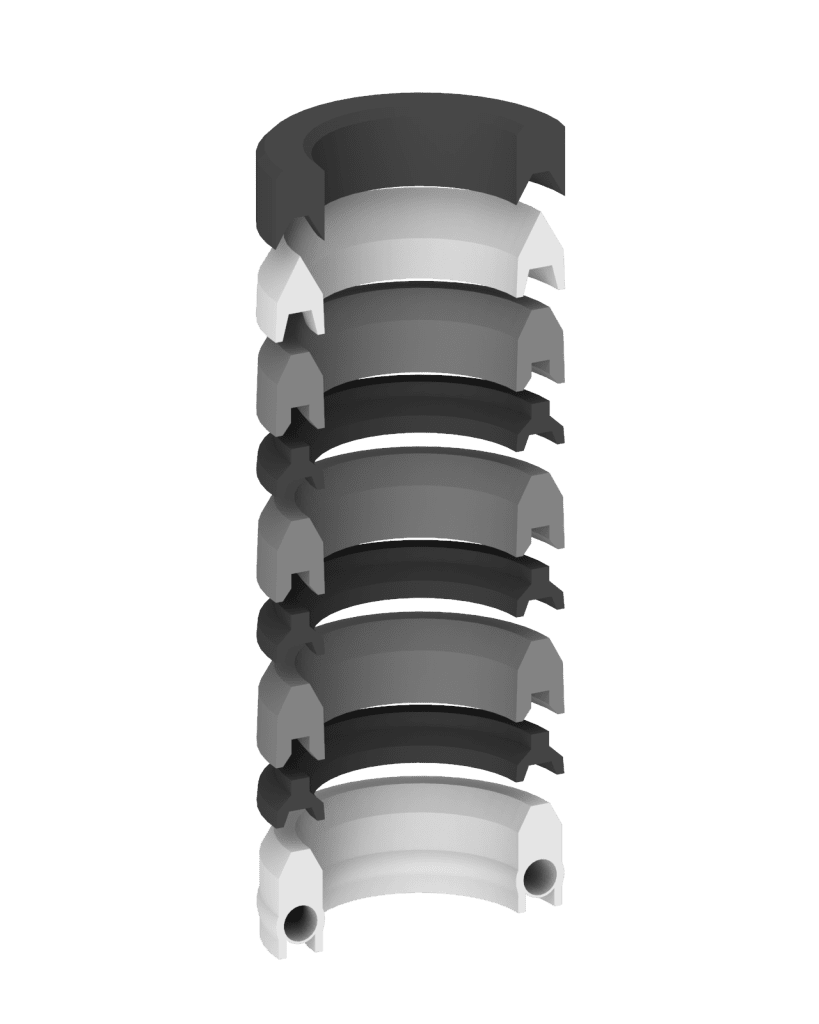

Severn have been investing a significant amount of R&D to address fugitive emissions in Control valves and their application requirements. By utilising a range of materials from filled graphite through to custom PTFE based compounds, Severn have, coupled with novel packing designs, been able to achieve tighter leakage rates than had previously achieved with standard packing sets. We have reduced control valve emission leaks to a minimum across our whole product range, without impacting on product performance and reliability.

The performance of valves with fugitive emission sealing systems are a critical consideration for the operator. Traditionally compression packings were simply tightened to ensure the seals were effective. This can increase friction reducing valve performance and controllability and leading to potential total valve failure.

Thanks to extensive testing carried out as part of Severn’s ongoing product research and development, we now have packing sets that achieve classes ISO 15848-1 A, B & C with valve processes from -196°C to +425°C and at pressures up to 10000PSI on both linear and rotary control valves.

An important consideration to take is that the operation cycles for an isolation valve to ISO 15848-1 can be as little as 201 cycles, while a control valve will have to achieve at least 20000, making the reliability of the sealing system a significant consideration and often necessitates a specifically designed sealing system. It is important that the correct specification is identified, Severn’s applications experts are on hand to help with this, drawing upon our unrivalled bank of valve and application data that forms part of Severn’s Repair Intelligence.

Working together with the client and implementing over 60 years of engineering excellence and valve knowledge we have at Severn, we ensure that true application needs are identified so that correct components are utilised in the product, avoiding the packing sets which may not be suitable for the application which could lead to significant valve performance issues.

Implementing these procedures and working with the client will help to achieve lower emissions from the valves population, which is a core imperative for our clients, with the global commitment to reduce harmful emission output on the back of COP26.

Severn also offer the ability to utilise its significant experience in sealing systems to retrofit customers existing valves from all OEM’s with innovative high integrity packing systems.

Meeting the challenge of fugitive emissions is just one of many methods that we help you, as our client, to meet your core imperatives of safe operations and minimum downtime.

If you have are having valve performance issues that are affecting your production capabilities, contact us today via the button below.

Deal expands specialist group serving the global severe-service valve market.

Gloucester, UK, 06 November 2021: Severn Group, the global family of specialist high-end valve engineering and manufacturing companies, which includes Severn and LB Bentley, has acquired US-headquartered ValvTechnologies, a leader in the design and manufacture of metal-seated, zero-leakage isolation valve solutions for demanding applications.

The deal, which follows the strategic partnership announced in June of this year, represents a step toward Severn Group’s vision to become the leading global severe service valve specialist in the energy and industrials sectors. ValvTechnologies will retain its operational independence, but will benefit from a broader pool of expertise and resources as part of the wider Group, alongside Severn and LB Bentley.

ValvTechnologies, Severn and LB Bentley represent an exceptional strategic fit. For example, where Severn excels in upstream oil and gas, and LB Bentley provides subsea specialisms, ValvTechnologies majors in mining and power. For Severn Group, this acquisition furthers a diversification strategy that will see the family of businesses increase its international presence, widen the industries served, expand its product offering and benefit from a combined approach to delivering on site service support capabilities across all markets.

As part of this transition, Mr. Kevin Hunt, has taken the decision to step down as President of ValvTechnologies. He will be handing over his day-to-day responsibilities to the existing leadership team, with Chad Bowers, previously Director of Manufacturing at ValvTechnologies, taking the role of President.

Perttu Louhiluoto, CEO of Severn Group, comments: “I would firstly like to thank Mr. Hunt for his 30+ years of dedication to ValvTechnologies, having led the development of industry leading products and playing an instrumental role in growing the business into the successful enterprise it is today. I have great confidence in the existing ValvTechnologies executive management team, and I am delighted to welcome Chad Bowers as he takes on the role of President.

“Our goal is to build an offering that better serves global demand for critical-application valves and aftermarket services in the energy and industrial sectors. We are incredibly confident that this deal will accelerate the growth of ValvTechnologies and the existing Severn Group companies, while significantly elevating our offering to current and prospective customers. With extended capabilities including enhanced global reach, product diversity and specialist solutions, we will provide customers with unrivalled support for the operational and assurance needs of their plants.”

Chad Bowers, President at ValvTechnologies, adds: “By joining Severn Group, we mark an incredibly exciting step in ValvTechnologies’ evolution. Our collective heritage in delivering engineering solutions for demanding applications will bring a strengthened offering to the market at a critical time for customers. Traditional core imperatives of safe operations and minimum downtime are increasingly coupled with a commitment to sustainability, and meeting these demands requires expert knowledge of asset life-cycle and process conditions. In joining Severn Group, this is exactly what we deliver – intimate knowledge of day-to-day operations, combined with relentless commitment to innovating severe service valve solutions for the future.”

This deal has been funded by Bluewater, the specialist international private equity firm. Bluewater originally invested in Severn Group in 2019.

About ValvTechnlogies

Part of Severn Group, ValvTechnologies was founded in 1987 and is headquartered in Houston, Texas. It is the leading manufacturer of zero-leakage, high-performance isolation valve solutions providing an unsurpassed level of severe service isolation services and reliability to customers in upstream and downstream energy, chemical processing, mining and minerals, pulp and paper and other specialised industries.

Severn on-site fire testing capabilities

At Severn, we don’t have to outsource fire testing for products to an external company which is both expensive and a timely process, even if the valve passes the test(s) first time.

We have our own on-site fire testing units across the Severn group, covering the latest ISO 10497, API 607, and API 6FA test specifications.

Having on-site fire testing capabilities across the group reduces cost for the customer when the requirement for firesafe certification in necessary. With a high success rate on our patented Triple Offset OCT range, it enables us to closely assess how the valves perform under extreme conditions and engineer them accordingly, which in turn gives us a high pass rate with some of our tests passing with minimal to zero leakage.

By understanding exactly how our products react in extreme circumstances and utilising Severn’s repair intelligence we can provide the most appropriate solution to our clients whilst maintaining the highest quality standards.

Having on-site fire testing facilities also means product/order turnaround is significantly quicker than other companies, who must outsource their product testing to test house in order to qualify the product. If a valve fails on test at our onsite fire testing facility, we can immediately identify and rectify the issue(s) and test the valve again. This reduces not only the time of testing and turnaround but also the overall cost to the client.

Severn verify the fire testing by having all tests witnessed by a 3rd party inspector.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.

If you want to find out more about Severn’s products and its testing capabilities, get in contact by completing our ‘Contact Us’ form.

Compressor anti-surge control valves for FPSO North Sea Client delivered three days ahead of schedule

Compressor anti-surge control valves for FPSO North Sea Client delivered three days ahead of schedule

Compressor Anti-surge Control Valves delivered three days ahead of schedule

Industry : Oil & Gas FPSO

Location: UK Central North Sea

Project: Two anti-surge control valves to be delivered within a tight time frame for UK Central North Sea Client

The Challenge:

A North Sea operator needed a solution for a technically challenging anti-surge application, required on a very short delivery schedule of 16 weeks, the initial requirement was for one valve to be delivered and the second valve to be delivered 10 days later.

Finding a solution:

The Severn team made initial engagement with the client to full understand the application and performance requirements that the customer needed.

A swift coordinated approach internally by Severn’s application and engineering team was needed and the teams worked closely together as it was imperative that the issue was identified quickly so a solution could be provided, manufactured and delivered within the 16-week delivery schedule.

The product:

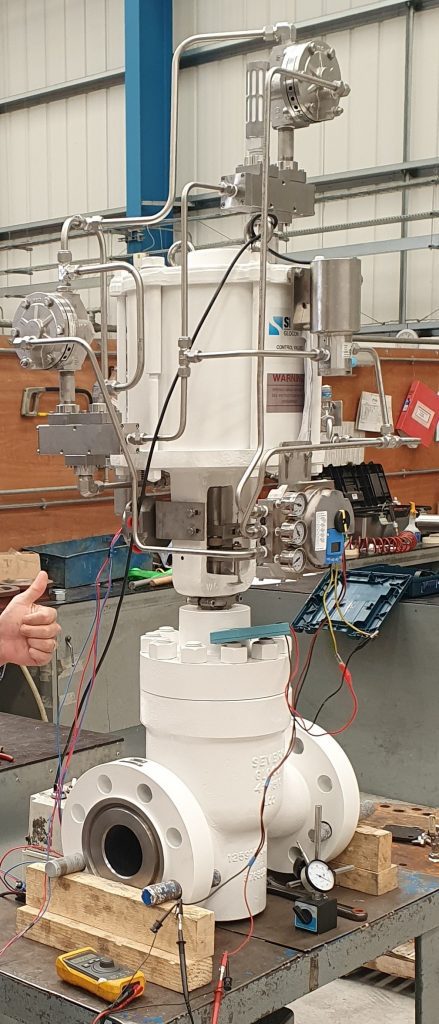

After identifying the clients requirements, the engineering team designed and manufactured two off 4” Cass 1500 RTJ Fig 5413 LTCS Body, SS/FC Trim, 14 Turn CCD, PC1N Pneumatic actuator with a Neles Positioner.

The positioner was revised mid order as per clients added operational requirements, the team was seamless in reacting to this change with no impact on the design or delivery schedule.

The outcome:

The contracts department managed the scope of the job and the challenges it brought professionally and with complete transparency; the client was kept fully informed throughout the production and delivery process.

The collaboration between the different departments and the constant engagement and the feedback with the client ultimately led to both valves being delivered three days in advance of the 16-week schedule, this was appreciated by the client.

The valve performed significantly well within the anti-surge required by the client for this application, especially on small step changes. This was a major issue with the clients previous valve, and an issue our team overcame with flying colours.

Severn requested to provide engineering support offshore on the asset, firstly with the installation and then subsequent valve commissioning activity.

” I want to take this opportunity to personally thank the entire Severn team for their continued focus and support during this project and more importantly, for getting both valves ready for shipping ahead of an already tight schedule.

Getting two high spec anti surge valves designed, assembled , and fully tested in less than 16 weeks is definitely an achievement” – Client representative

Mars Valve UK, a Severn company, have recently secured a 10-year agreement with Mars Taiwan to become the sole UK distributor.

Despite the agreement taking longer than initially thought to achieve, the work from Rhys Jones, Chief Commercial Officer Severn Group and Sarah Jamison, Senior Legal Counsel Severn Group, has helped greatly to get this agreement over the line and put in place a much more robustly secure agreement that will help Mars Valve UK with its continued business growth.

‘This new agreement also displays the high level of trust built up over the last 12 months between Mars Valve UK and Mars Taiwan, after what was a difficult time for the business. The level of hard work put in day in, day out from the Mars Valve UK team is second to none and the results for such a small team are outstanding. The whole team is looking forward to continuing this growth over the next 12 months and beyond‘ – Wayne Lyons, Business Manager, Mars Valve UK

If you want to find out more about Mars Valve UK, and its UK distribution with the securing of the 10-year agreement with Mars Taiwan then get in touch below.

Mars Valve UK Ltd is the UK master distributor for Mars Valve Taiwan.

Established in 1997, Mars Valve Taiwan, design and manufacture a large range of stainless steel ball valves for a range of industrial applications.

Mars Valve UK Ltd was formed in 2000 and has grown from strength to strength, we have a excellent technical knowledge of over 28 years in the UK valve industries, we have gained a global reputation for the quality of its valves and the aftersales service provided.

Mars Valve’s channel to market is through a series on regional master distributors – who represent the product, and ensure local stock and technical support provides the service orientation.

Severn Celebrates 21 years in Aberdeen.

Advanced valve engineering capabilities underpin success in the gruelling offshore oil and gas environment of the North Sea.

Enhancing the performance of existing offshore platforms has been a priority for North Sea oil and gas operators over the past two decades. With production steadily declining, finding ways to improve efficiency has been critical.

During this time, Severn has played an important role supporting leading operators with valve management and maintenance services as well as highly-engineered valve products. Longstanding client relationships are a defining feature of Severn’s business.

In 2010, Severn opened a dedicated Aberdeen facility to work in tandem with its established plant operations based then in Huddersfield and now in Brighouse. At the time, the Aberdeen team focused on the supply of traded isolation valves for North Sea operators. Today, the team works in close alignment with Brighouse under the direction of Managing Director David Brennan, as Severn’s hub for North Sea valve supply, servicing, testing and management and now Severn celebrates 21 years in Aberdeen, we are looking forward to the next years of growth and success.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.

United Kingdom, 23rd June 2021: Severn Glocon UK Valves Limited and ValvTechnologies have reached an agreement to form a strategic partnership that will see collaboration between two of the world’s leading engineering and manufacturing companies specializing in innovative, high-end, severe-service valves.

Subject to regulatory approval in the U.S., Severn and ValvTechnologies strategic partnership will combine the brands’ distinctive and complementary capabilities to extend the global reach, product offerings and customer service of both companies. Backed by Bluewater, the international energy private equity firm, the collaboration will see many customer and sales synergies that will offer significant added value to the marketplace.

Headquartered in the UK and with premises worldwide, notably manufacturing facilities in India, Severn specializes in control, choke and small-bore subsea valves for the energy industry. Headquartered in Houston, Texas, ValvTechnologies also has premises worldwide, and is the global leader in the design and manufacture of metal-seated, zero-leakage, severe-service valve solutions for the harshest applications.

Kevin Hunt, President at ValvTechnologies, comments: “Both Severn and ValvTechnologies have a long history of mutual respect. Now, working more closely together, we can provide a broader range of engineered solutions to the severe-service marketplace. That’s great news for our customers.”

Steve Waugh, Chairman of Severn, adds: “Each company has been founded on technical prowess and commitment to innovation. Through this new combined force for the global valve market, we believe we will provide an enviable range of solutions and services in our industries.”

About Severn

Founded in 1961 and headquartered in Gloucester, United Kingdom, Severn Glocon UK Valves Limited is a leading manufacturer of control valves and related products worldwide. The company offers a wide range of severe service control, choke and general service valves, associated actuators and peripheral equipment, bespoke built special application control & choke valves, providing valve management as well as general engineering support services to oil and gas, LNG, power and other process plant users.

About ValvTechnologies

Founded in 1987 and headquartered in Houston, Texas, ValvTechnologies is the leading manufacturer of zero-leakage, high-performance isolation valve solutions providing an unsurpassed level of severe service isolation services and reliability to customers in the fossil power, nuclear generation, upstream oil and gas, downstream and chemical processing, mining and minerals, pulp and paper and other specialized industries.

About Bluewater Bluewater is a specialist international private equity firm focused on the middle-market energy sector. Its experienced investment and operating professionals drive value creation as they manage $2.5billion of investment across a portfolio of 22 companies. Today it has a prime focus on projects or technologies that contribute to the energy transition agenda, and works to a diversified investment strategy based on the principles of sustainability and close working partnerships with best-in-class management teams. It has a strong focus on ESG, and is a signatory to the UN Principles for Responsible Investment.

Media contacts

Severn makes ice-road deadline.

An ice-road waits for no one, so Brighouse engineers had their work cut out ensuring six butterfly valves were ready to reach a north Russian LNG plant before the spring melt.

The order comprised four 20” ASME 300 and two 16” ASME 900 double flanged short pattern triple offset butterfly valves.

To ensure Severn makes the ice-road deadline, the Brighouse team designed, manufactured, assembled and tested the valves in-house, comfortably shipping them by the mid-March deadline.

Manufactured in CF8M with electric actuators, these control valves surpassed the customer’s Class IV leakage requirement, achieving the more challenging ‘Class VI or better’ standard.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.

Severn celebrating 20 years with Shell.

Back in 2000 Severn Unival secured a valve management contract for Shell’s North Sea platforms. Each time the contract has come up for renewal we have retained the business. The contract was recently renewed again, marking 20 years of working together. The strength and duration of this customer relationship are testament to the high level of service and technical expertise we bring and is a major factor in Severn celebrating 20 years with Shell.

Severn manufactures and supports high quality valves for the energy industries. Its control, choke and small bore subsea valves are pre-eminent in the global market, underpinning the reliability and high performance of business-critical client infrastructure.

Severn’s global reach, technical prowess, and collaborative approach – all founded upon a heritage of British engineering excellence – help to assure production continuity for clients and reduce the prospect of costly downtime.

Its understanding of the life-cycle of assets positions Severn to offer end-to-end engineering solutions, enabling clients to meet their core imperatives: safe operations and minimum downtime.