Severn’s Engineering Heritage and Technical Expertise Lead to Extended Design Feature for Trip Offset Butterfly Valve

Posted: 5 August 2024The Triple Offset Butterfly Valve Cutting Edge Design Features Leads to Comprehensive Application Coverage.

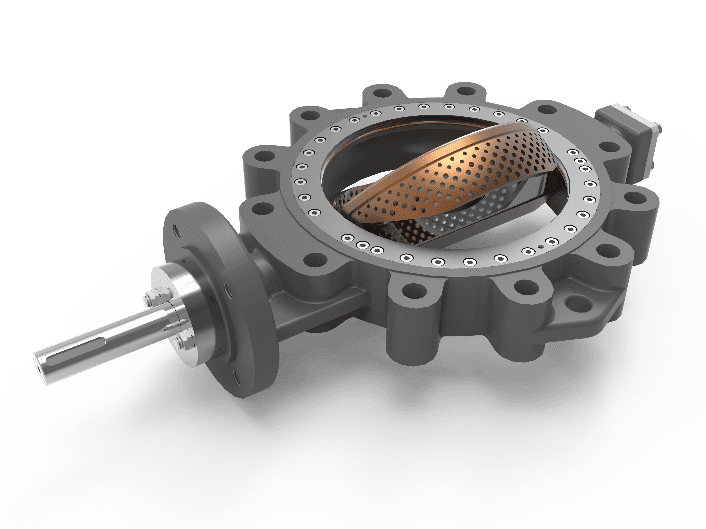

Incorporating over 60 years of engineering excellence and technical expertise in valve engineering and application, Severn offers an industry leading and patented engineering technology solution(s) for Butterfly Valve requirements and applications with the Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. By utilising Severn’s ‘Repair Intelligence’ knowledge which involves providing real market feedback from extensive in-depth analysis from failed valves. Severn have designed each facet of the OCT TOV Butterfly Valve to provide the most accurate, reliable, and robust service capability and performance possible to help the end user achieve their core remit of safe operations and minimum downtime.

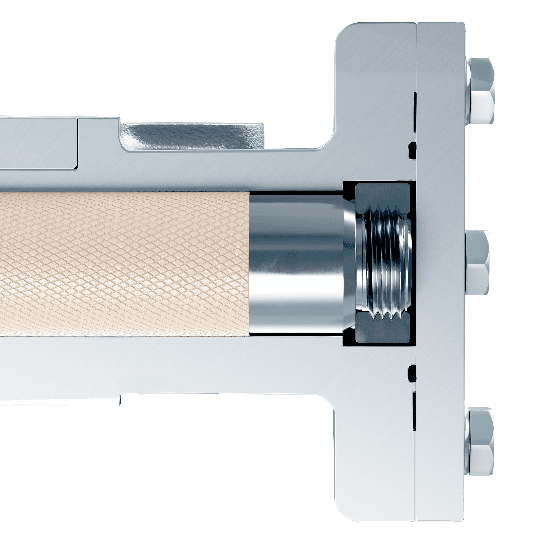

Severn’s OCT design uses circular sealing geometry, unlike traditional triple offset designs that use an ellipse. The benefit of circular geometry is that it provides a uniform sealing load around the circumference of the sealing diameter, providing a reliable and repeatable shut-off. By using circles rather than ellipses, it allows Severn to use proven circular sealing knowledge and incorporate this into the TOV Butterfly Valve.

In addition, to this we can also add specialised flow control trims that are traditionally found on double offset valves. These control trims include Anti Cavitation / Low noise, half baffle & full baffles. We can also add special features such as steam jacket and purge ports should they be required, onto our Triple Offset design.

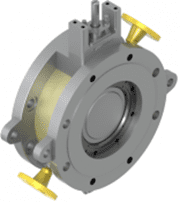

Process conditions can change with time. Severn have ensured the interchangeability of the seal, should the sealing requirement not become as critical, or process conditions become more arduous. The HS seal can be changed to a laminated seal, or if conditions dictate, a solid seal. This can be done without the need for main valve components being replaced. The complete in-field serviceable valve can be upgraded on site without the need for specialist tools or knowledge ensuring possible down time and loss in production is kept to a minimum.

The interchangeability and versatility of the seal allows for Severn’s Triple Offset Valve to be used for both isolation and control applications and processes. The diversity of the OCT TOV Butterfly Valve and its functional usability for an extensive range of both isolation and control applications leads to the potential savings in stock holdings for end users who can use stock this one valve instead of stocking two. This in turn allows for potential cost savings for the end user on stock holding by reducing the need to stock multiple valves due to the extensive coverage that the OCT TOV Butterfly Valve offers.

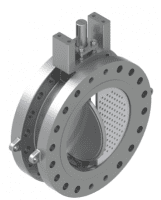

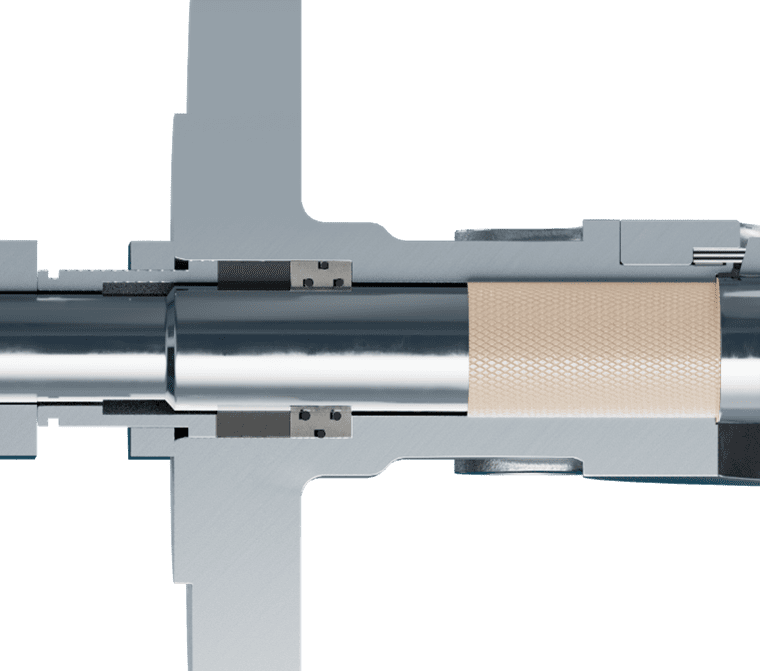

Severn have designed all their Triple Offset Butterfly Valves with safety as paramount and therefore engineered the product with anti-blowout at both ends of the valve. This negates any chance of the shaft blowing out. The reduced shaft diameter at the drive end ensures the shaft cannot blow out through the packing follower and anti-blowout ring on the threaded shaft end ensures positive engagement without the need for additional fasteners.

The OCT range also comes with hard facing on the disc as standard with options to upgrade the standard hard facing to weld overlays such as stellite 6, ensuring and reliable seal and extended service life.

A quarter turn design ensures ease of actuation for both control and isolation purposes. Whether this be via an actuator or gearbox, the quarter turn design allows for simple operation.

As standard, Severn’s OCT TOV Butterfly Valve includes fugitive emission packing to ISO 15848 with options to change to meet customer specific requirements such as Shell 77/312 available.

The OCT valve range has been firesafe tested & certified in accordance with the strict fire test specifications set out in the standards ISO 10497, API 607 & API 6FA. Withstanding extreme temperatures of up to 1000°C whilst still sealing. Further underpinning the performance capabilities and validating the valve performance, ensuring this valve can be suitable for an extended range of applications and process requirements, leading to safe operations and reduction unplanned downtime for the end user.

Severn offer the OCT TOV Butterfly Valve in all cast materials. From basic carbon steels to specialist alloys such as Monel, Titanium & Hastelloy. Severn can provide the correct material selection for your application. Additional surface coatings such as stellite, armoloy, chrome or weld overlays are available upon application and request.

More News

All News- Posted: 17 November 2025 Butterfly Valves in Fire Water Systems – Tackling Galvanic Corrosion

- Posted: 17 November 2025 Butterfly Valves in Fire Water Systems

- Posted: 15 October 2025 Severn TrimGuard – Advancing Impact Resistance in Choke Valves

- Posted: 21 July 2025 The Critical Role of Valve Spares in Effective LNG Control

- Posted: 21 July 2025 LNG’s Ultimate Line of Defence

- Posted: 14 July 2025 Severn’s Anti-Surge Valves Satisfy Rigours of Dynamic Testing, Without Concession