Severn Future Proof Butterfly Valve with Versatile Design Feature

Posted: 12 August 2024Severn’s engineering heritage and technical expertise have led to the OCT TOV Butterfly Valve being future-proof for changes in the process conditions to provide increased versatility for the end user.

From the outset, Severn made flexibility a key driving force in the design of the Oblique Cone Technology (OCT) Triple Offset (TOV) Butterfly Valve. Due to Severns extensive diverse engineering heritage and excellence, our expert team of engineers understand that processes and application product demands change over time, whether it is the process conditions or the overall requirements of the valve for the end user. Due to this understanding, the Oblique Cone Technology Triple Offset Butterfly Valve has been designed to incorporate multiple seal options, all fully interchangeable with each other, providing maximum application diversity and usability to ensure safe operations and minimum downtime.

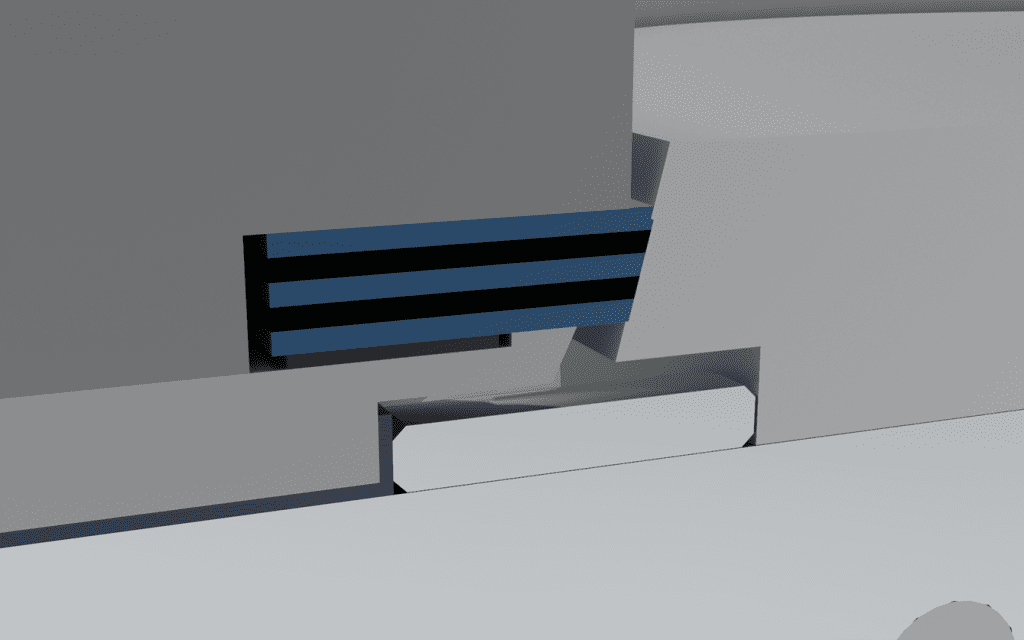

The Laminate seal is the “traditional” Triple Offset Valve seal and consists of multiple metal and graphite layers providing isolation sealing.

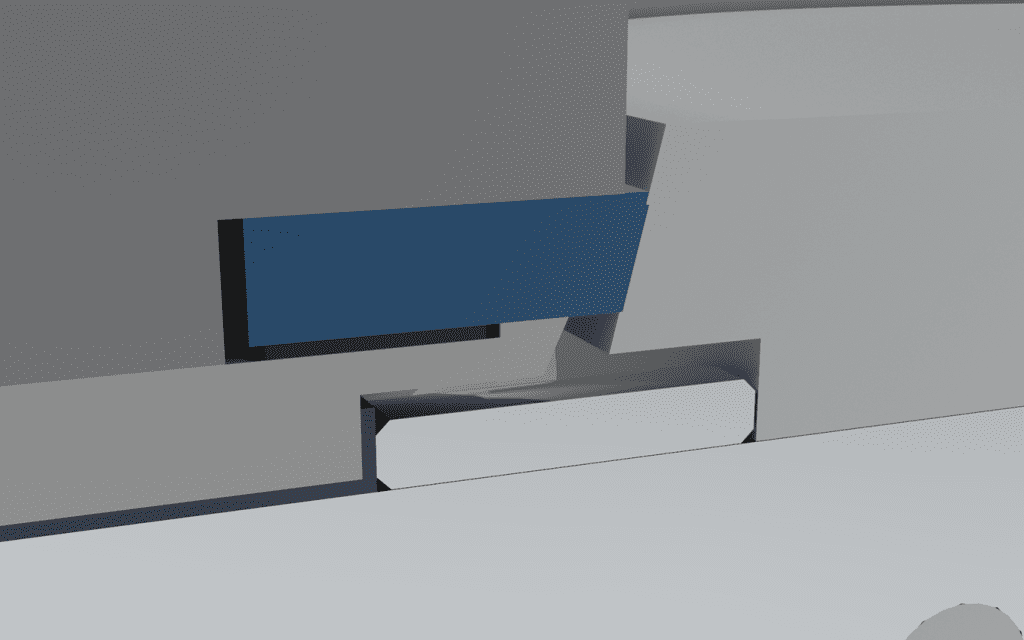

The OCT HS seal is a hybrid polymer metallic seal, this seal benefits from a primary metal seal and secondary polymer seal, this provides a reliable and repeatable bubble tight seal time after time. This can also be paired with PTFE packings when graphite being in contact with the line media is a concern. The polymer seal is fully compliant with EN ISO 80079-36 (ATEX).

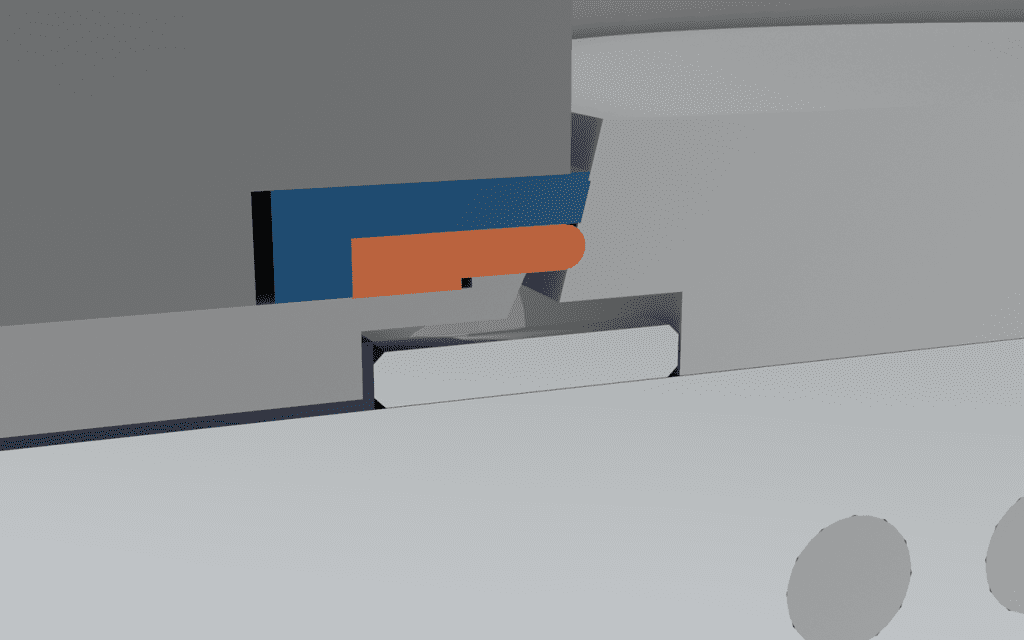

The OCT SW Valve takes the hybrid sealing to the next level with its versatile high performance. Severn utilises the OCT-HS seal and has designed a valve that ensure there is no graphite in contact with the line media to remove the risk of costly galvanic effects such as internal corrosion leading to valve failure. Whilst doing so the OCT-SW also maintains firesafe certification.

Should the sealing requirement not become as critical, and process conditions become more arduous, the Laminate and Hybrid seals can be changed for the OCT-SS solid seal. As the name suggests it is a solid metallic seal, that can be made from hard-wearing alloys to add longevity to the sealing life of the valve in arduous conditions and can offer a control valve seat leakage.

Based on Severns comprehensive history of severe service control, our team of engineering experts work closely with operators and end uses to identify the correct seal and material selection to provide the maximum reliability and productivity further ensuring minimum downtime.

All the OCT seals are interchangeable and can be upgraded without the need for main valve components being replaced, further emphasising the OCT TOV Butterfly Valves versatility. The fully in field serviceable valve can be upgraded on-site without the need for specialist tools or knowledge, this further ensures that costly unplanned downtime and site waste is kept to a minimum, along with potential loss in production for the end user. All the seal options can be changed on site within a small space of time to ensure site maintenance costs are reduced by upgrading the existing valve rather than discarding and replacing with a commodity product each time.

Each OCT valve is specially designed to be versatile and ensure it has multiple purposes for multiple conditions whilst still delivering maximum performance. With the introduction of the interchangeable seal, these can be easily swapped out to match the end users’ requirements, should they change.

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 25 November 2024 Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions