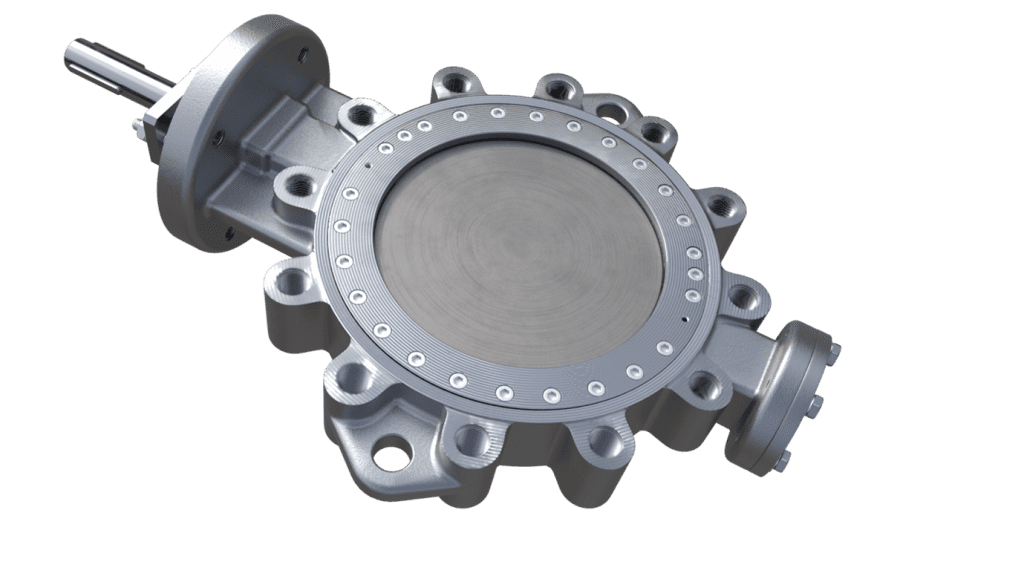

Severn’s OCT TOV Butterfly Valve Goes Beyond Meeting Safety Accreditation

Posted: 15 July 2024Exploring the innovative features and engineering principles of Severn’s OCT TOV Butterfly Valve that puts safety first.

At Severn, safety is paramount in the design of our products. With our background in safety-critical industries, Severn understands the importance of safety first for both our customers and employees.

As well as adhering to the strictest industry standards, Severn have identified that shaft blowout prevention was paramount to our end users and the wider industrial and process industries for improved valve performance and reduced operational downtime.

Butterfly Valve shafts are designed to connect to the disc with either dowel pins, taper pins, or keyways. The separation of the shaft and disc in service can be catastrophically dangerous. If any of these parts fail, the shaft may be ejected from the valve body. Shaft blowouts can occur when a coupling mechanism fails, therefore, disconnecting the shaft from the disc. With the pressures in the system, it may eject the unrestrained drive shaft through either end of the valve.

Not only is this projectile a huge safety concern but has the potential to compromise the pressure envelope of the valve allowing process to escape into the atmosphere.

Severn has designed all their Triple Offset Butterfly Valves as standard with anti-blowout incorporated at both ends of the valve. This negates any chance of the shaft blowing out if the pins were to fail. The reduced shaft diameter at the drive end ensures the shaft cannot blow out through the packing follower.

On the blank end of the valve, Severn have multiple features which prevents shaft blowout. The anti-blowout ring on the threaded shaft end ensures positive engagement without the need for additional fasteners. The blank end plate is locked in place and is designed to withstand full rated test pressures.

Dual anti-blowout devices are standard on the OCT TOV Butterfly Valve, meaning that even if the gland is removed, the secondary internal anti-blowout device will stop ejection of the shaft under the pressure, thus increasing both operator and plant safety.

Severn have designed their Triple Offset Valves to exceed the minimum wall thicknesses stated in ASME B16.34. Instead of just using the minimum allowance, Severn have gone above and beyond to ensure the safety of our products in the field for our customers.

Within Severn’s Triple Offset Butterfly Valve is a corrosion allowance. This means that the valve can afford to concede material to corrosion over time without affecting the pressure containing integrity or safety of the valve. The amount of corrosion may vary depending on the environment the valve is working in, but due to Severn’s engineering heritage and excellence, the OCT TOV Butterfly Valve has been designed to withstand changes in working environments and process conditions.

High MAST figures and safety factors are key when designing the Triple Offset Butterfly Valve. MAST is the Maximum Allowable Shaft Torque a quarter turn valve shaft can withstand during operation without mechanical failure. With Severn using higher MAST figures on their Triple Offset shafts, this helps maintain the structural integrity of the valve.

Sizing actuators correctly is a credit to Severn’s engineering excellence. Actuators, gearboxes, or any form of obturator that drives a quarter turn valve must be sized correctly by using the correct input and output torques. By torque testing the physical products prior to final inspection, we can compare the physical torques against our theoretical torques to maintain accuracy and consistency across the range.

Safety has always been at the forefront of Severn’s designs, and this is paramount in the 8500 Butterfly Valve range.

More News

All News- Posted: 17 November 2025 Butterfly Valves in Fire Water Systems – Tackling Galvanic Corrosion

- Posted: 17 November 2025 Butterfly Valves in Fire Water Systems

- Posted: 15 October 2025 Severn TrimGuard – Advancing Impact Resistance in Choke Valves

- Posted: 21 July 2025 The Critical Role of Valve Spares in Effective LNG Control

- Posted: 21 July 2025 LNG’s Ultimate Line of Defence

- Posted: 14 July 2025 Severn’s Anti-Surge Valves Satisfy Rigours of Dynamic Testing, Without Concession