Emergency Overhaul for 6” 600 Control Valve For North Sea Operator

Industry:

Oil & Gas Offshore

Location:

Aberdeen North Sea

Project:

A North Sea Operator needed an emergency overhaul for a 6” 600 Anti-Surge Globe Control valve that had shutdown production due to damage upon commission whilst being commissioned on site.

The Challenge:

A North Sea operator contacted Severn in relation to a major operational issue that had occurred with a valve offshore that had shutdown production due to damage from the commissioning of the valve on site.

A quick solution was required to minimise production downtime, which is Severn’s core strength, with a history of providing highly technical solutions with rapid return around times to ensure our client’s assets are fully optimised.

Finding a solution:

The technical teams in Aberdeen and Brighouse worked cohesively to provide the best solution to the client and within two days the damaged valve was received in our Aberdeen workshop.

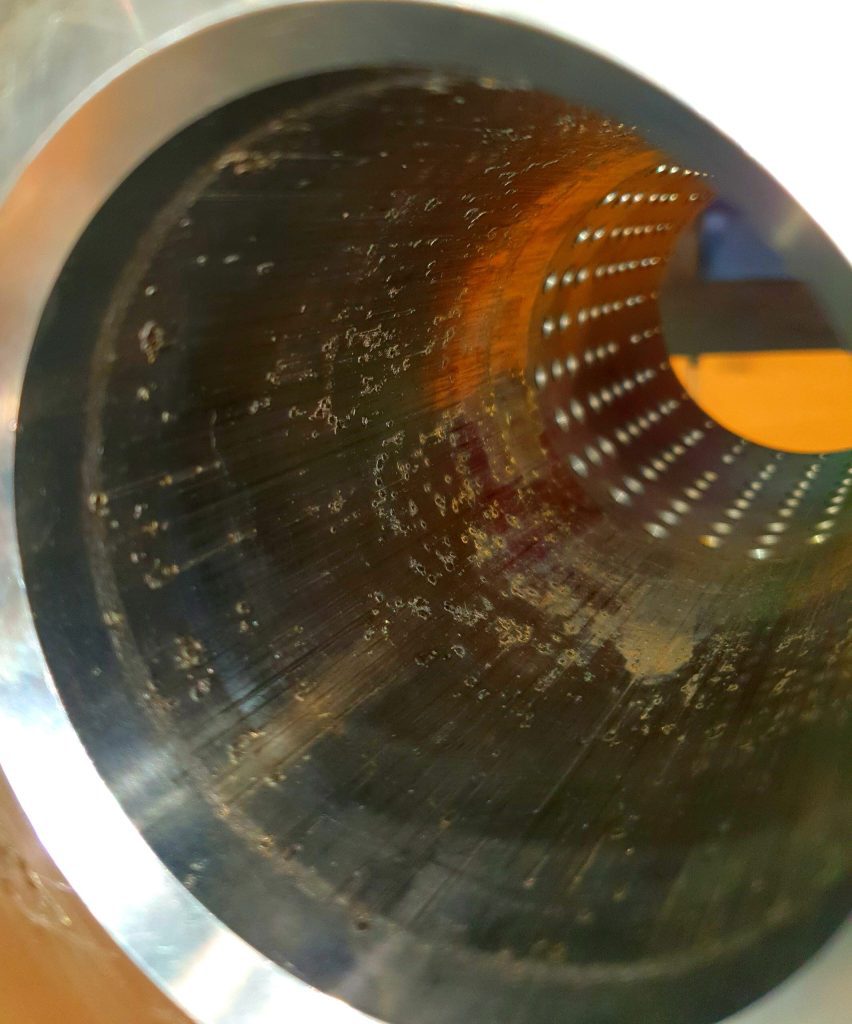

Upon inspection of the valve, the team discovered the internal surfaces had severe scoring on the plug, stem and cage.

After initial inspection, measurements were taken in line with the original design to identify the acceptable tolerances that needed maintaining before overhaul could take place.

The Product:

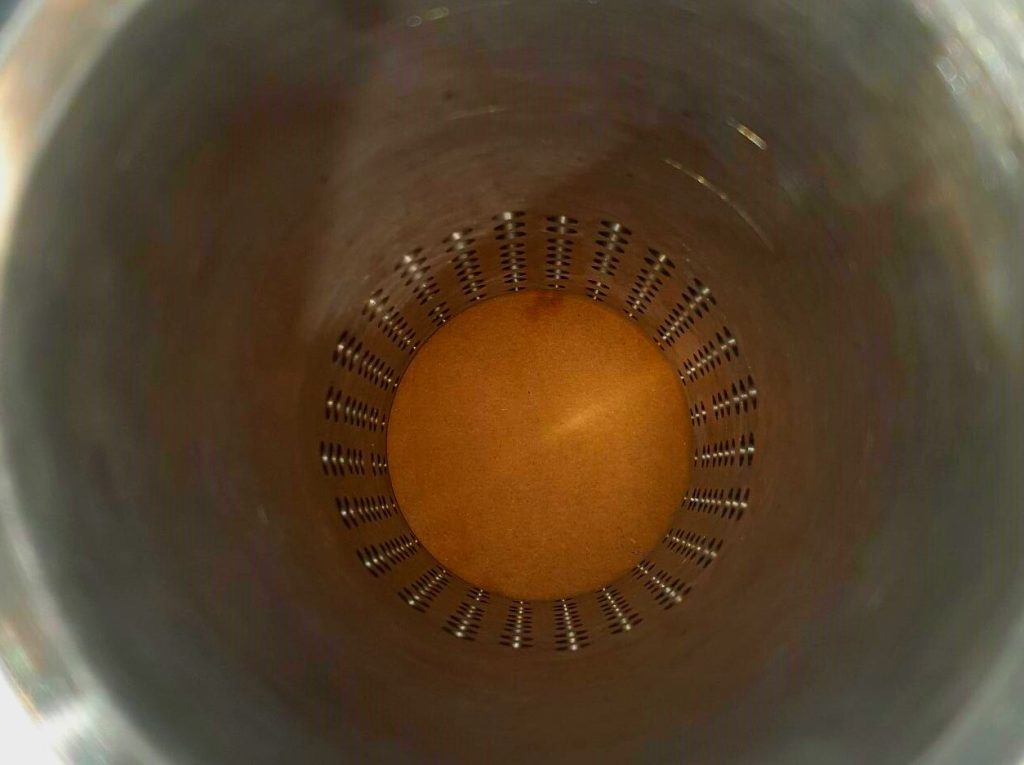

The overhauled issued valve was a 6” 600 RF FIG 1415 Compressor Anti-Surge Globe Control Valve, compromising of a A995 4A body with a duplex SS/Stellite FC trim and a 4CC Cage 130Cv.

The outcome:

The co-ordinated action plan between the technical teams in Aberdeen and Brighouse meant a fast track turnaround could be achieved with an efficient solution for the clients problem. This emergency overhaul was vital to the clients key objectives, minimum downtime and safe operations.

Two weeks after initial contact from the client regarding major operational issue, the valve was expediated back to the customer minimising production downtime significantly.

”We were delighted with the service offered, the level of technical expertise combined with an understanding of the criticality of this work scope ensured a quick turnaround of the valve and minimised the impact upon production.

The regular communication and updates were crucial in ensuring that we could plan accordingly for the return of this valve.

We have since engaged with Severn on the back of this work, primarily as a result of our first experience”.– Client Representative

If you want to read more of our case studies, you can find them by clicking the Case Studies button below or if you would like to contact us with an application, engineering or other valve query than click the contact us button.

Alternatively, you can download the full stage case study via the download button below.