Emergency Sealant Enables On Stream Butterfly Valve Repair

The challenge

Mitigating the wear and tear of pipeline systems is an enduring concern for plant managers. Valves are especially vulnerable to abrasion from hydrocarbon fluids. The flow medium comes into contact with internal components such as the seat, which plays a vital role sealing a valve. Over time, deterioration is inevitable and repair work needs to be undertaken.

Butterfly valves are particularly challenging. Since they don’t have a cavity, it’s traditionally been difficult to reseal them effectively without removal from the line. Butterfly valves have a high installed base in most processing facilities due to their compact design and cost-effectiveness. However, their ongoing repair and maintenance can result in costly unplanned downtime.

The solution

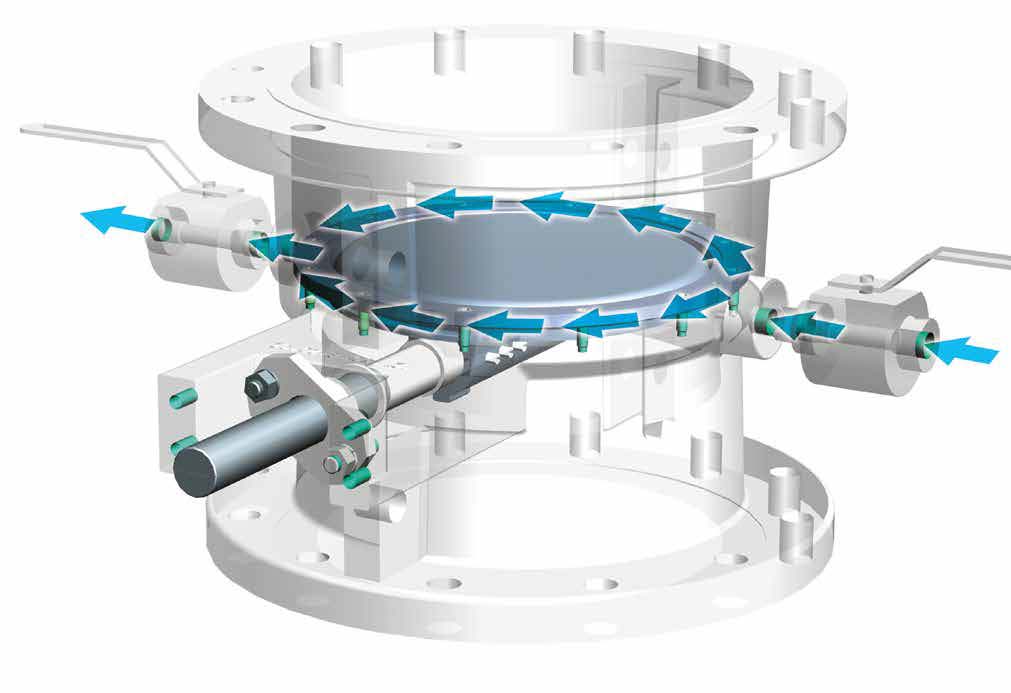

Severn has developed a progressive technology to overcome this challenge: SPIRES® (Sealant Pressure Injection Reserve Endurance System). The solution incorporates an emergency sealant system as a fundamental design feature of butterfly valves. Should the primary seal fail, a secondary sealant is injected into a runner behind the disc to compensate for any seat leakage when the valve is closed.

Since the sealant system is wholly independent of the main seals, damage to the main seals does not affect its operation. The objective is to achieve a bubble-tight shut-off, even if the seat is badly damaged, avoiding the need for unplanned downtime. SPIRES® offers the capability that plants are accustomed to with ball valves with sealant injection ports. However it also brings the benefits of cost, face to face options and low weight associated with butterfly valve design.

The outcome

Saudi Aramco has conducted a stringent performance assessment of the SPIRES® technology. A test specimen’s soft seat was damaged with cuts of 26 different depths in four locations. Depths varied from 0.004 inches to 0.036 inches to simulate severe seat leakage. The butterfly valve was connected to a test rig and a nitrogen flow was established, reaching ANSI class 150 operating pressure at 19.5 bar. This resulted in a leak rate of around 1,200 l/min.

The sealant was then injected through one of the ports to close gaps at a pressure of approximately 2000psi at the pump. This resulted in the closure of the nearest group of cuts. The further group was closed when injection was switched to the other port. At this point, total valve sealing was established and pressure started to build up to the required level. Next, the pressure was dropped to zero and the tubular run was checked, with no abnormality detected. The results of this validation testing show that SPIRES® offers an effective solution to repair damaged butterfly valves in situ. Deploying the technology can result in a reduction in unplanned maintenance, increased uptime and better plant safety.

SPIRES® enables badly damaged butterfly valves to be repaired in situ. If you want to read more of our case studies, you can find them by clicking the Case Studies button below or if you would like to contact us with an application, engineering or other valve query than click the contact us button. Alternatively, you can download the full stage case study via the download button below.