Severn’s engineering heritage and excellence has led to the innovative design of a product that can master both Control & Isolation applications.

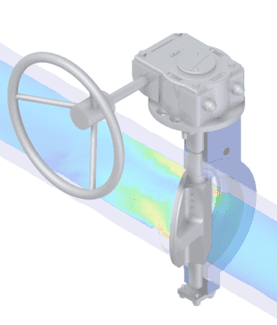

Utilising Severn’s long history with Control Valve design, our team of engineering experts have been able to manufacture a Triple Offset Butterfly valve that can be used to provide superior control in both throttling and modulating service, whilst additionally providing a repeatable seal for isolation duties.

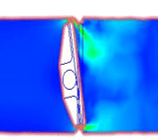

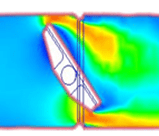

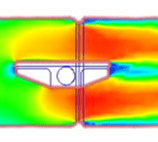

By designing a Control Valve that can isolate, rather than an isolation valve that controls (which may initially sound the same but is vastly different), Severn have designed a Butterfly Valve that maximises the Cv with streamlined internals to provide optimal flow characteristics when controlling the process.

We have also eliminated the need to have fasteners on the disc or a bolted-on seal, thus enabling us to optimise the disc profile. Additionally, by removing fasteners from the disc, we have eliminated the risk of loose fasteners falling into the line due to vibration.

By adopting a body-mounted seal we have been able to increase longevity & reliability of the product. As we have taken this out of the flow path of line media, this reduces wear on the seal allowing Severn to maximise the bore size for an increased CV.

Using our Patented Oblique Cone Technology (OCT), we can also use circular sealing geometry which provides an even seal load around the circumference of the disc. This gives us repeatable bubble-tight sealing, improving product performance, reliability, and safety, ensuring you achieve your core remit of safe operations and minimum downtime.

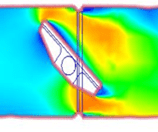

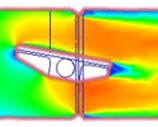

The OCT geometry enables Severn to add an extensive range of trims to the valve not traditionally found on Triple Offset Valves. By utilising a one-piece disc, Severn can add anti-cavitation trims, when conditions dictate, to help control the flow. This can also be paired with baffle plates when needed, enabling a Butterfly Valve to be utilised when severe service conditions may mean a standard Butterfly Valve would not be suitable or would have a significantly reduced service life.

The OCT Triple Offset Butterfly Valve can be utilised for both control and isolation valve applications, enabling the end user to significantly reduce stock inventory and overall operating costs. Parts are standardised and interchangeable, meaning end users can have a reduced spares inventory leading to further cost reductions.

It also provides the end users with the option to potentially utilise one valve that can perform both the control and isolation functions within a system, rather than two – leading to significant reductions in operating and service costs and weight saving – this can be paramount for weight critical operations such as offshore installations.

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 25 November 2024 Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions