Understanding the Innovative Oblique Cone Technology in Severn’s OCT TOV Butterfly Valve

Posted: 24 June 2024Explore the design that has been inspired by engineering heritage and excellence to create a product that master’s isolation and control applications.

From the outset, Severn wanted the Oblique Cone Technology (OCT) to be unique in the Triple Offset valve market. Severn wanted to develop a product that not only solves an extensive range of issues for the customer with our “standard” product range, but to break tradition, and to design and manufacture a technically superior Butterfly Valve.

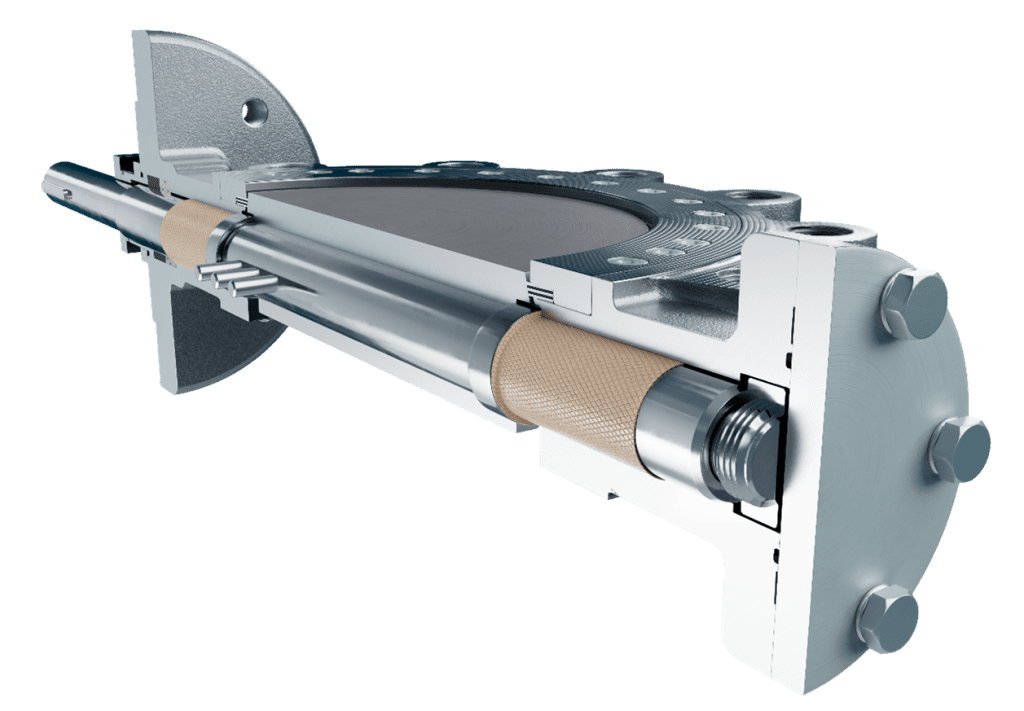

By utilising their comprehensive history with specialist butterfly valve design and manufacture, Severn have been able to develop a Triple Offset Butterfly Valve that performs both control and isolation duty in a single package. A valve designed from the outset to be re-used, upgraded, and provide an increased level of safety to the end user.

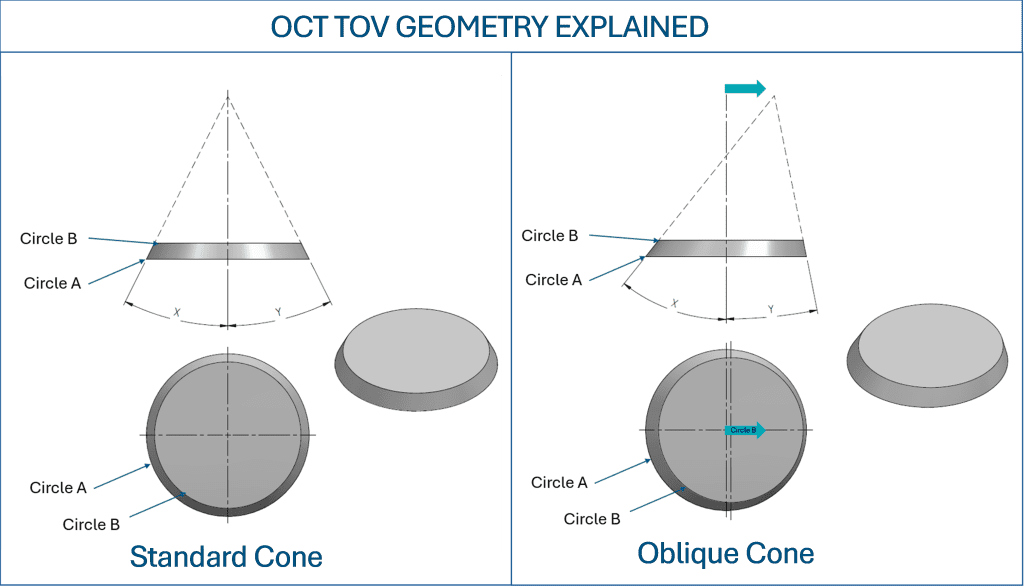

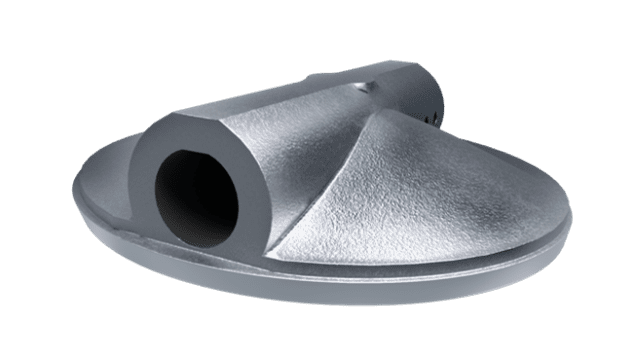

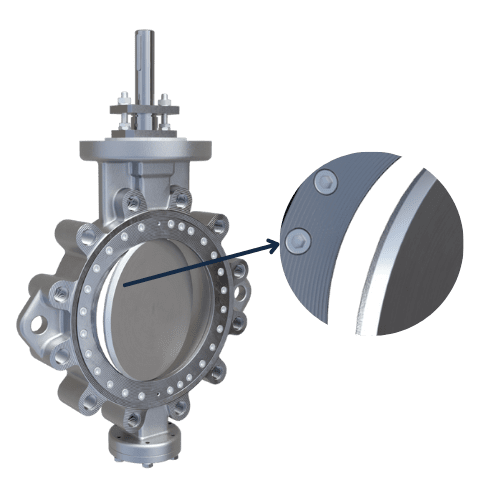

Severn have utilised its years of experience in manufacturing both the concentric and double offset Butterfly Valves to create innovative technology that pushes the boundaries of Triple Offset Butterfly Valve design. By looking at the traditional elliptical sealing concepts of Triple offset valves and combining this with circular sealing principals, Severn created its patented Oblique Cone Technology (OCT). In its most simplistic form, the geometry can be compared to a circular cone, by moving the point of the cone along one axis, this creates two different angles to the cone sides (forming an oblique cone), by taking a slice of this cone, it forms the sealing geometry of the OCT valve.

The benefit of this method means we maintain the principals of circular seals, thus providing an even seat load all-round the disc, therefore providing increased flexibility within the design to allow Severn to add different sealing options to the valve as well as specialist control trims such as anti-cavitation / low noise trims.

By understanding the foundational principals of Butterfly Valve design, Severn have a detailed knowledge of the interaction between each and every Butterfly Valve component. This combined with Severn’s Repair Intelligence philosophy and over 60 years of engineering excellence, customer solutions and end user feedback, problems can be anticipated and resolved before they occur and therefore increasing the lifecycle of the product and reducing costly unplanned downtime.

Severn additionally want to break the cycle of Butterfly Valves being a “throw away’’ commodity items. The OCT TOV Butterfly Valve is designed to be re-used, repaired, or upgraded on site with only basic tools. The robustness of the design means that the main components can be cleaned, soft goods replaced, and the valve can be reinstalled to provide extended years of reliable service. This not only reduces long term cost of ownership for the end user, but also reduces the environmental impact of the plant operations. Severn also install Fugitive Emission certified packing as standard in the OCT to further reduce the plant emission.

Flexibility and reliability come as standard in the OCT TOV Butterfly Valve. By using the principals of a Control Valve, Severn have streamlined and reduced the disc thickness to impede the flow as little as possible and maximise valve Cv. Fasteners have been removed from the disc, to eliminate the risk of them coming loose due to vibration and falling into the pipeline. The seal has also been mounted in the body rather than on the disc. This not only protects the seal by removing it from the direct flow path, but means the disc is thinner as well as giving Severn the option to add anti cavitation / low noise trims onto the disc when process conditions dictate.

The OCT principle has been installed and operating in the field for over 10 years without issues, this coupled with countless amounts of testing and validation including fire testing, pressure testing, temperature testing and cycle testing, provide the end user with confidence in the robustness and reliability of the OCT Triple Offset Butterfly valve range and ultimately minimise down time and plant costs.

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 25 November 2024 Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions