Severn’s Cryogenic valve range is developed from our years of extensive Control valve knowledge and experience.

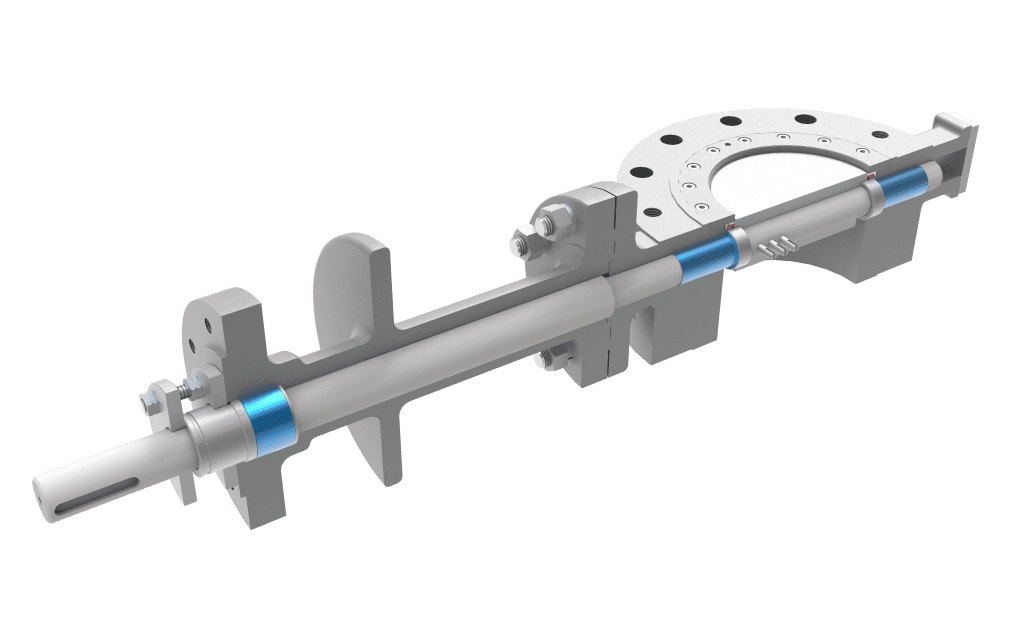

We have developed our 8500 ranges for cryogenic applications. Open or closed extension bonnets are available for all our valve products, ensuring the gland packings are located away from the line media.

By utilising the principles of our 8100, 8300 and 8500 valve ranges, we can offer a vast range of products from a Single Offset Swing Clear valve, a Double Offset PTFE Seated valve, or a Triple Offset valve, all specifically tailored for cryogenic services.

Clients can also choose from standard and bespoke face to face and end connection options. With access panels available on Butt Weld End designs when required.

Severn’s Cryogenic Butterfly valve series offers the flexibility in design for assurance in performance and ensures you maintain and achieve your core imperatives of safe operations and minimum downtime.

Design Features:

- Interchangeable laminated & hybrid seal options

- Disc supplied hard faced as standard for improved abrasion resistance

- Metal seated for arduous conditions

- Torque seated design ensures consistent sealing performance

- Self-compensating design for wear and temperature

- Torque energised seal for low & high pressures

- Self-compensating design for wear and temperature

- No internal bolting to come loose due to vibration (not BWE)

- Disc supplied hard faced as standard for improved abrasion resistance

- Available with a range of low noise and anti-cavitation trims

- Fully in-field serviceable

- Reliable performance

To find out more about the Cryogenic Butterfly Valve range, download the brochure via the downloads box on the right hand side or view the interactive version below.

If you have a Control Valve based enquiry, you can contact the Severn team by completing the enquiry form located here.