Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

Posted: 25 November 2024Severn Glocon’s Control valves are engineered to meet the stringent requirements of ISO 15848-1, specifically achieving Class A certification for fugitive emissions for pressure ratings up to #2500 which is best-in-class. ISO 15848-1 sets rigorous standards, classifying valve performance based on their ability to contain emissions.

Conventionally, Class A packings are required when any Mutagenic Carcinogenic chemicals, methane, toxic media, hazardous gases and sour gases are suspected to be evident. It is reported that the Oil & Gas industry is responsible for 15% of global energy-related Green House Gas (GHG) emissions. Due to this reported figure, it becomes vital to address these emissions through valves.

Why is ISO 15848-1 Critical for Fugitive Emissions?

This ISO standard evaluates valve sealing performance against fugitive emissions, which can be unintended leaks of volatile or hazardous gases. The certification involves multiple tests, including temperature and pressure cycling, as well as leak rate assessments. Notably, Severn’s valves are capable of meeting the highest (Class A) for stem and body seals, ensuring leak rates remain minimal which is crucial for handling hydrogen sulphide-rich sour gas applications in the Oil & Gas sector.

Technical Aspects:

Severn Glocon’s compliance with Class A specifications under ISO 15848-1 includes advanced seal design that undergoes stringent helium detection testing. In these tests, valves are exposed to high pressures, and leak rates are assessed using sensitive equipment like a helium mass spectrometer leak detector (MSLD). The rigorous testing provides assurance of valve integrity, even under extreme thermal cycling, mechanical cycling, and varying pressures.

Meeting the Challenges of Sour Service:

Valves in sour service handle gasses containing H₂S, which is both highly toxic and corrosive. Severn’s use of specialised materials and advanced sealing techniques ensures resilience against corrosion and leak prevention. This positioning enables Severn to offer reliable solutions that comply with the environmental regulations, prevent harmful emissions, and support the sustainability objectives of Oil & Gas operators.

Ready for High-Sour Service Applications

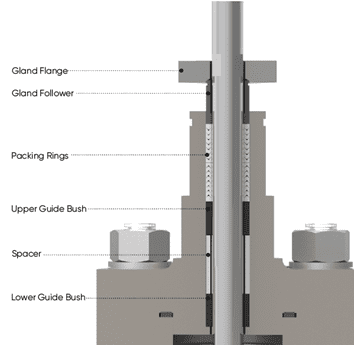

Severn Glocon’s valves, equipped with FE Gland Packing, are capable of withstanding the highly corrosive environments typical in sour gas applications. The materials and unique sealing mechanisms ensure reliability and minimise corrosion between the stem and packing material, reducing the frequency of maintenance while ensuring top-tier emissions control.

Contact the Severn team of experts for best-in-class engineering assistance with your valve operational issues:

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions

- Posted: 12 August 2024 Severn Future Proof Butterfly Valve with Versatile Design Feature