The revolutionary Severn OCT® technology introduces hybrid sealing technology to the Triple Offset Valve (TOV), with interchangeable seals and dual anti-blowout design, ensuring our TOV meet the most stringent of specifications.

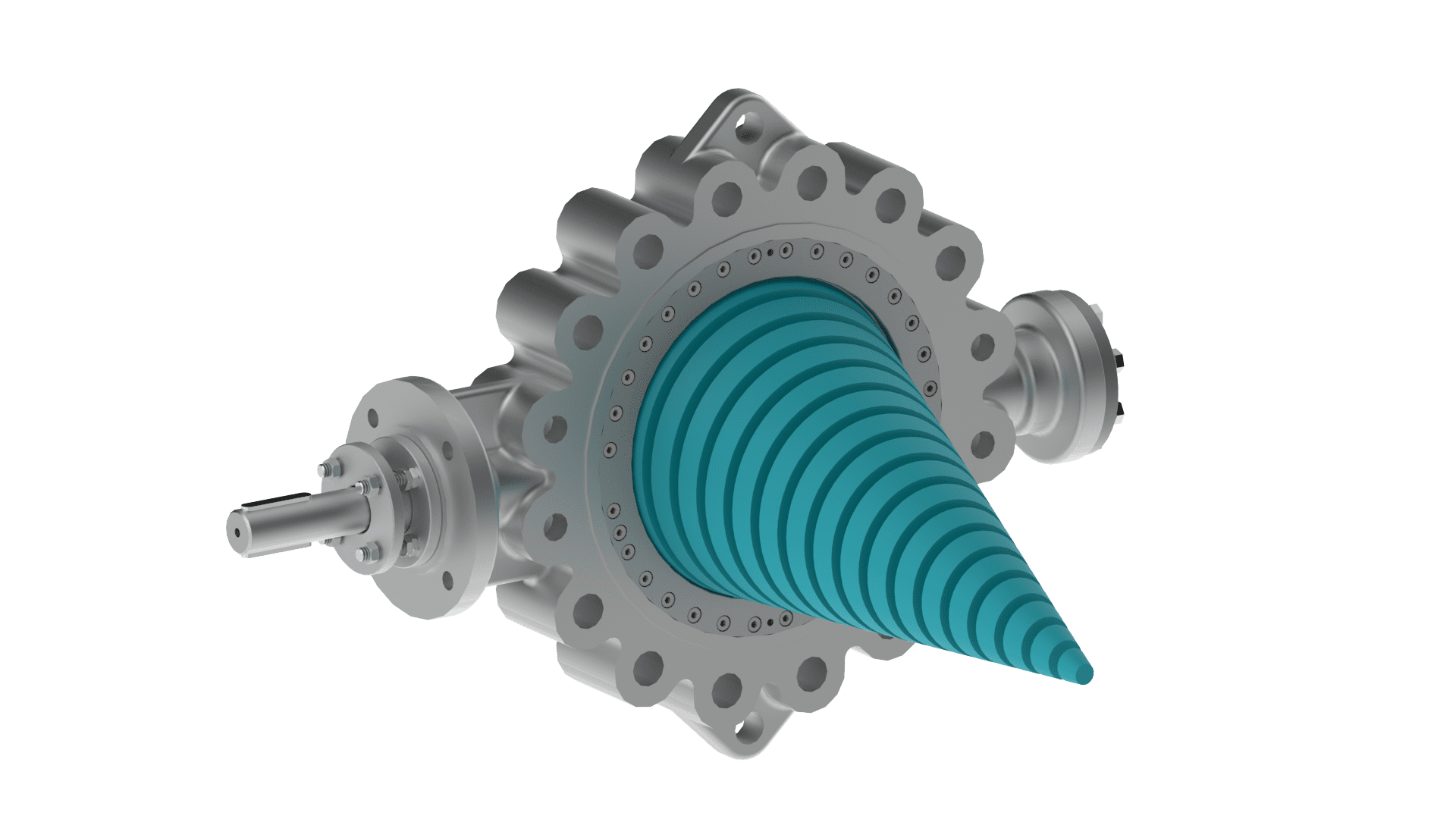

When comparing Triple Offset valves (TOV) to Double Offset valves, on paper the valves can appear to be very similar. However, there is a distinct advantage to using the more technical offering that comes with a TOV. The conical shape of the disc and seal offers repeatable sealing and extended service life. Severn’s patented OCT® technology enhances the traditional TOV, and these enhancements will be explored further in the article.

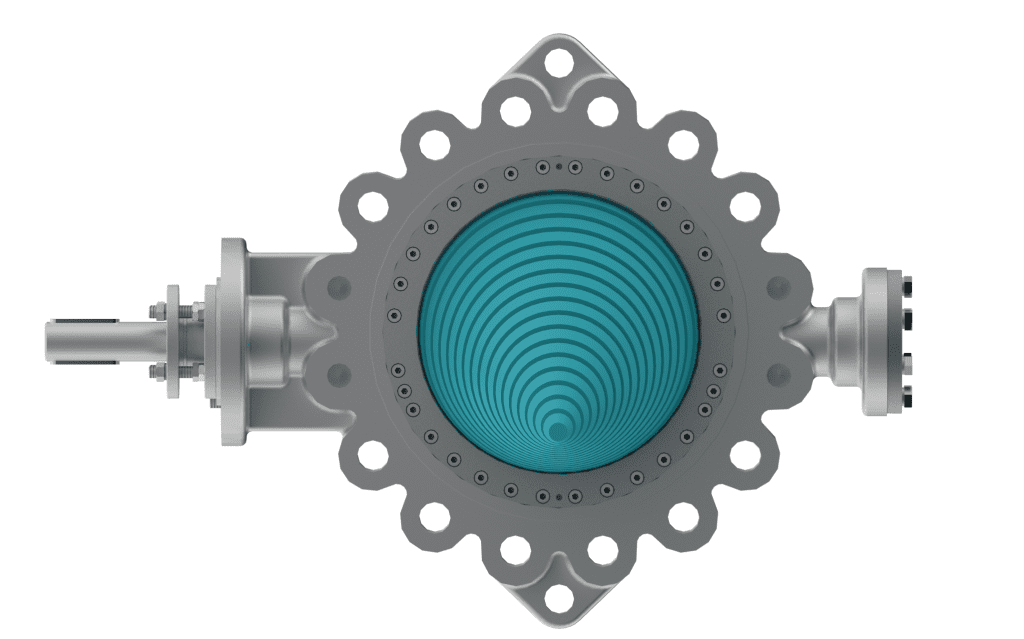

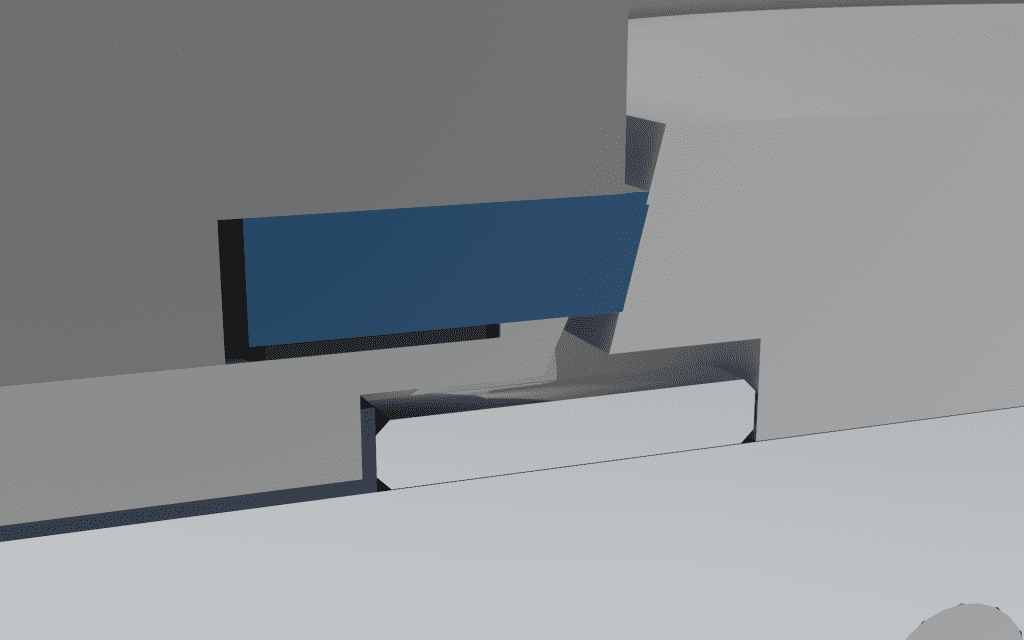

The Oblique Cone Technology (OCT®) moves away from the traditional elliptical shape and provides circular sealing geometry, allowing proven Double Offset sealing knowledge being incorporated into the TOV. We can utilise trims that are traditionally found on double offset valves, such as an anti-cavitation trim, making the TOV the ultimate valve for both isolation and control application specifications.

The TOV is self-compensating for wear, meaning consistent sealing performance is achieved time after time. The camming action of the third offset reduces seal wear by minimising seal contact. The disc and seal only contact each other in the last 1-2° of operation, not only minimising wear but also reducing friction. Comparing this to a Double Offset valve, which contacts for 10° of operation.

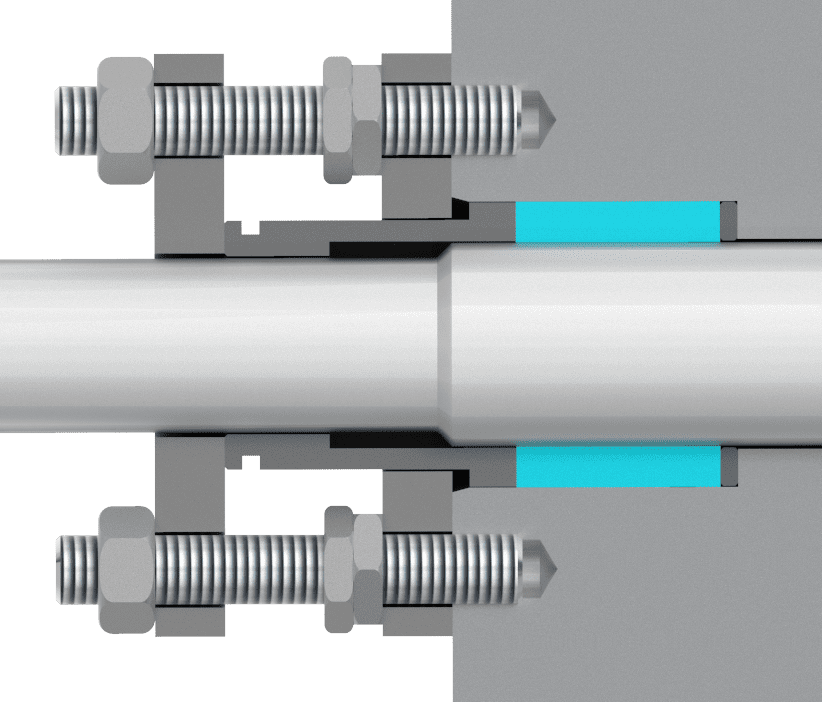

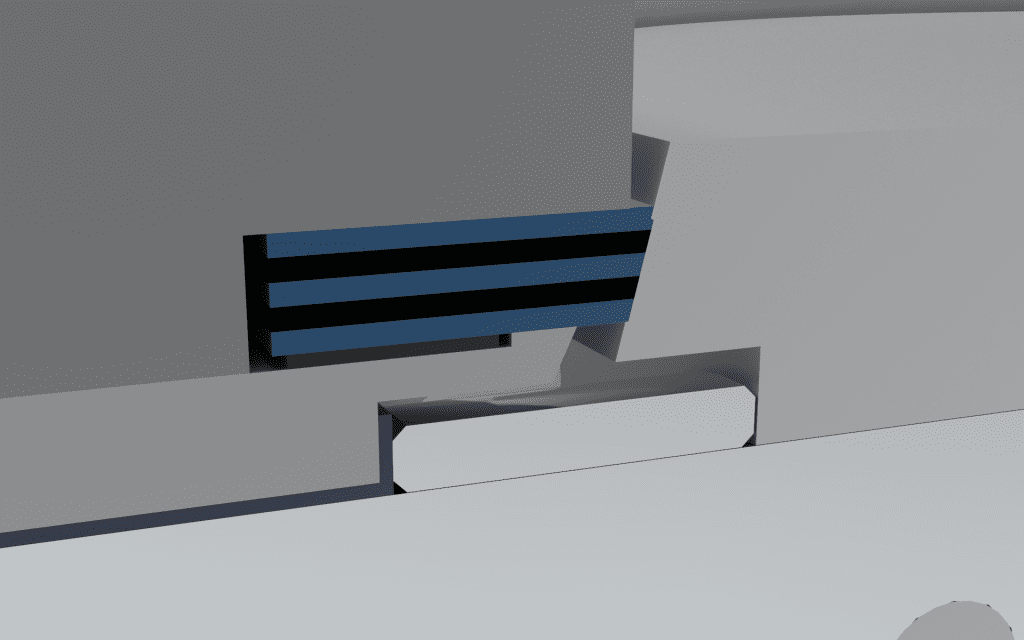

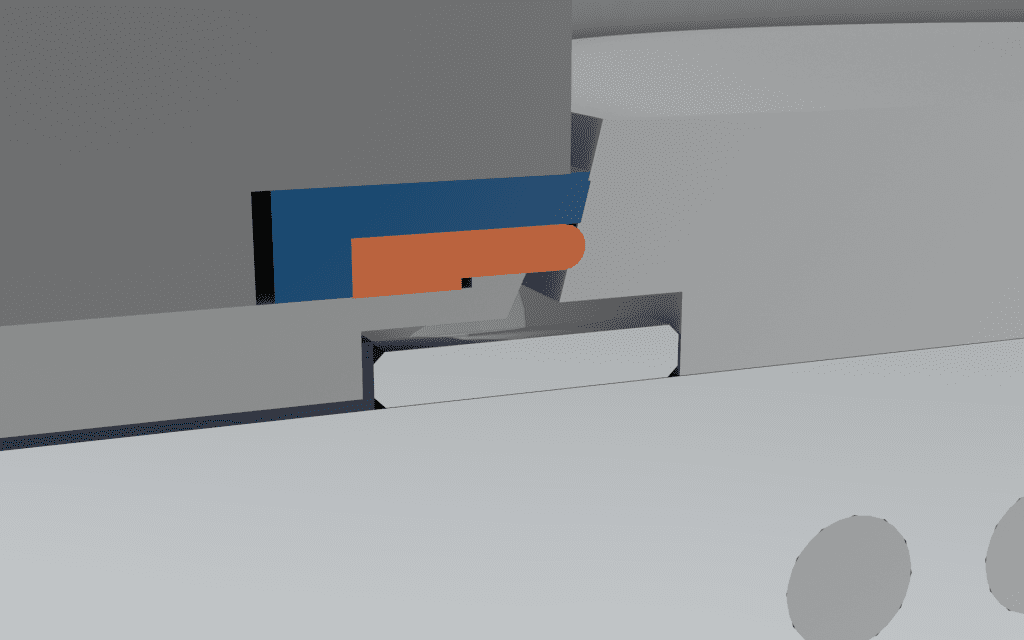

Severn’s investment in Research & Development has been key to introducing hybrid sealing technology to the TOV. By utilising our hybrid polymer metallic seal, we can apply the self-compensating benefits of the TOV to a polymer seal. Partnering a Polymer with the metallic element of the seal, means that should the soft seal become damaged in operation, the metal seal will take over and provide a reliable seal.

The hybrid seal has undergone a strict regime of testing, including cycle and fire testing, proving that even in extreme conditions, the valve can still provide a seal with zero leakage. Should damage occur to the Double Offset it is unlikely to achieve an acceptable level of sealing meaning the seal would need replacing resulting in unplanned and costly downtime.

The standard design of the TOV incorporates the requirements of the most stringent specifications. Dual anti blowout design comes as standard, ensuring the shaft cannot be ejected from the valve. The polymer seal is fully compliant with EN ISO 80079-36 (ATEX) requirements.

As time goes on, things change. That is why we have ensured the interchangeability of the seal, should the sealing requirement not become as critical, and process conditions become more arduous. The HS seal can be changed to a laminated seal, or if conditions dictate, a solid seal. This can be done without the need for main valve components being replaced. The complete in-field serviceable valve can be upgraded on site without the need for specialist tools or knowledge.

If you require further technical information on the 8500 and 8500 OCT Triple Offset valve series, please refer to the product page via the button below:

More News

All News- Posted: 20 January 2025 Meet the Severn IEW 25 Team

- Posted: 25 November 2024 Severn Secure Success with Sour Service Application and Fugitive Emissions Leakage Rate A

- Posted: 29 October 2024 Severn Aberdeen: Your Go-To Partner for OEM and Third-party Valve Solutions.

- Posted: 23 October 2024 Severn Glocon Launches New Engineering Centre of Excellence, Furthering Commitment to Engineering Innovation and Expertise

- Posted: 26 August 2024 Unlocking Unrivalled Performance: Severn’s OCT TOV Butterfly Valve Dominates Seawater Applications

- Posted: 19 August 2024 Severn Offer Technical Solution to Combatting Fugitive Emissions